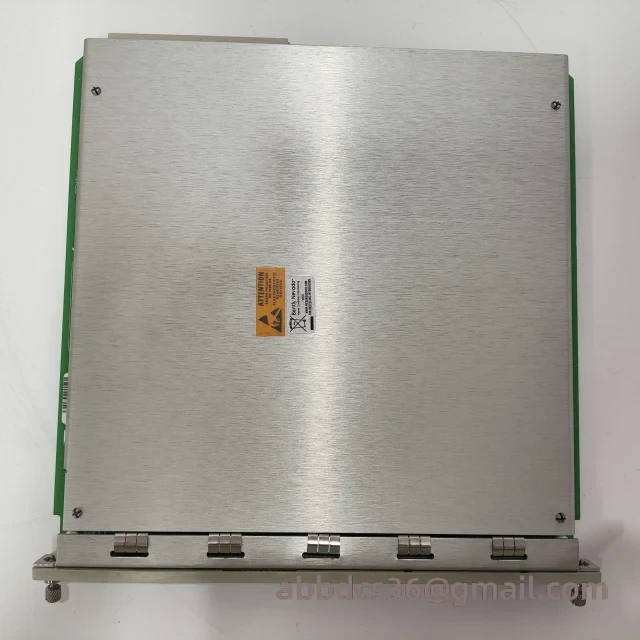

Bently Nevada 3500/32 125712-01 Vibration Monitoring Module

In power plants, refineries, and heavy industrial facilities, the Bently Nevada 3500/32 125712-01 serves as a critical vibration monitoring solution for rotating machinery. Designed for integration into turbine generator sets, centrifugal compressors, and critical pump systems, this module continuously tracks vibration velocity and displacement to prevent mechanical failures.

| Specification | Details |

|---|---|

| Manufacturer | Bently Nevada (General Electric) |

| Model Number | 3500/32 125712-01 |

| Input Channels | 2 (differential) |

| Measurement Range | 0-25 mm/s velocity / 0-100 μm displacement |

| Output Signals | 4-20 mA analog + relay contacts |

| Communication | Modbus RTU (RS-485) |

| Certifications | ATEX, IECEx, FM, CSA |

| Mounting | DIN rail (35mm) |

This module forms the backbone of predictive maintenance systems in challenging environments. For example, an oil & gas client in Kuwait recently implemented it to monitor offshore platform compressors, achieving 30% reduction in unplanned downtime. The 3500/32 works alongside proximity probes, tachometer modules, and data acquisition systems within Bently Nevada’s 3500 framework.

We stock complete 3500 system components including 3500/15 speed monitors, 3500/22M phase reference modules, and 3500/42M communication interfaces. Our engineers can help configure complete protection systems for steam turbines, gas turbines, and rotating equipment trains. Personally, I’ve found this module particularly effective in paper mill applications where moisture and vibration create challenging operating conditions.

Our Value Proposition

We offer global availability through our 16 regional warehouses, with standard delivery in 5-7 business days. Every unit comes with a 12-month warranty covering both parts and performance. Our technical team provides free configuration support and application guidance – just last week we helped a mining client in Australia integrate this module with their existing SCADA system using Modbus RTU protocol.

For current pricing and availability, please contact Linda via WhatsApp, email abbdcs36@gmail.com, or visit our Hong Kong warehouse at ABB-WORLD, 235 Golden Horse Street, Tsim Sha Tsui.

*Specifications subject to verification against specific application requirements. Technical documentation available upon request.

There are no reviews yet.