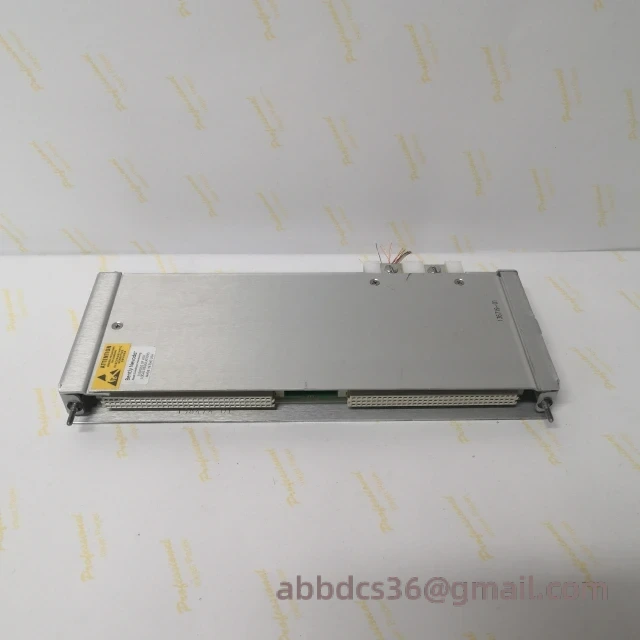

BENTLY 136719-01 Vibration Monitoring System

Engineered for precision diagnostics in rotating machinery, the BENTLY 136719-01 system provides continuous vibration analysis critical for predictive maintenance. Commonly deployed in turbines, compressors, and industrial pumps, this solution helps operators identify imbalance, misalignment, or bearing wear before failures occur.

| Specification | Details |

|---|---|

| Manufacturer | Bently Nevada |

| Model | 136719-01 |

| Operating Voltage | 220V AC |

| Frequency Range | 10 Hz – 10 kHz |

| Sensitivity | 50 mV/g ±5% |

| Environmental Temp | -40°C to +120°C |

| Certifications | CE, ISO 9001 |

| Enclosure Material | 316 Stainless Steel |

This system integrates seamlessly with Bently Nevada’s 3500/3300/1900 platform architectures. We frequently handle related components like 3500/22M interface modules and Proximitor probes for complete monitoring solutions. A recent client in the oil & gas sector reported 40% fewer unplanned shutdowns after deploying this system across their pipeline compressors.

Our inventory includes both standard and obsolete Bently Nevada models. With 16 regional warehouses globally, we typically achieve 2-5 business day delivery. Every unit undergoes functional testing before shipment and carries our standard 1-year warranty. For current pricing or to verify stock status, contact Linda directly via:

WhatsApp: +86 190 6659 1275

Email: abbdcs36@gmail.com

Hong Kong Warehouse: ABB-WORLD, 2-8 Golden Horse St, Tsim Sha Tsui

While specifications look impressive on paper, what matters most is field performance. Personally, I’ve seen this system catch early-stage bearing failures in paper mill dryers that vibration technicians missed during manual checks – that’s the value of continuous monitoring.

There are no reviews yet.