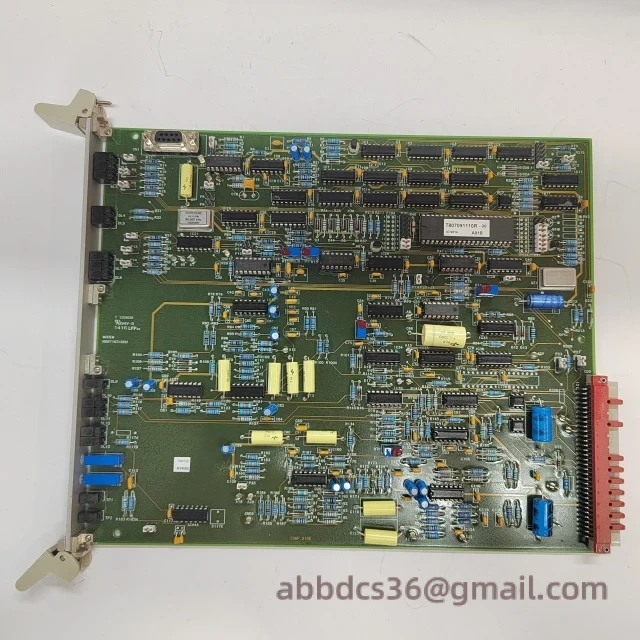

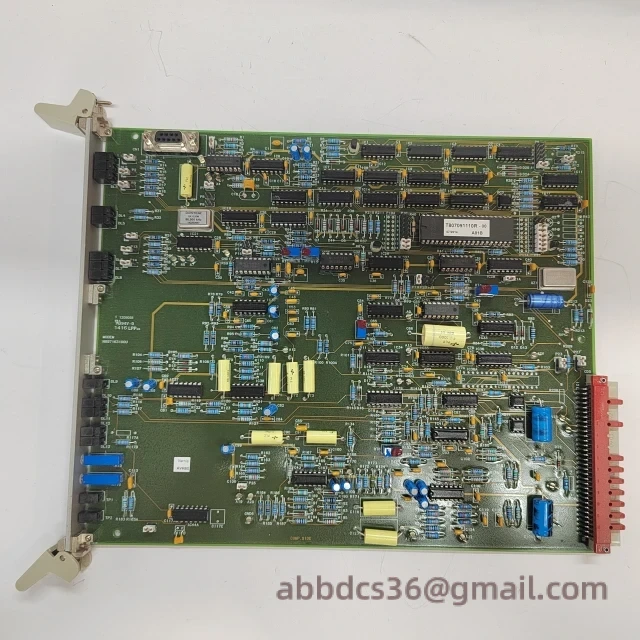

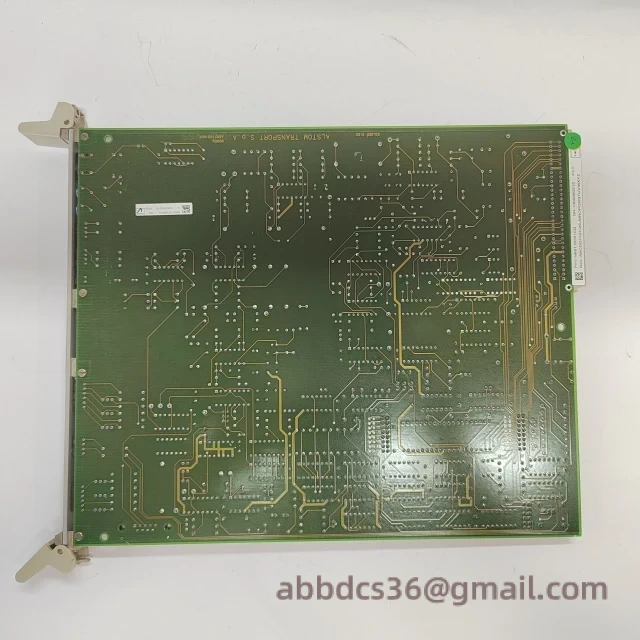

ABB N897163510Q/N897163050Q Modem Module

Designed for mission-critical industrial environments, this ABB communication module ensures rock-solid connectivity between automation systems and remote devices. Its triple redundancy architecture handles harsh factory conditions while maintaining sub-millisecond response times – perfect for oil & gas pipelines needing real-time pressure monitoring or manufacturing plants requiring uninterrupted PLC communication.

| Specification | Details |

|---|---|

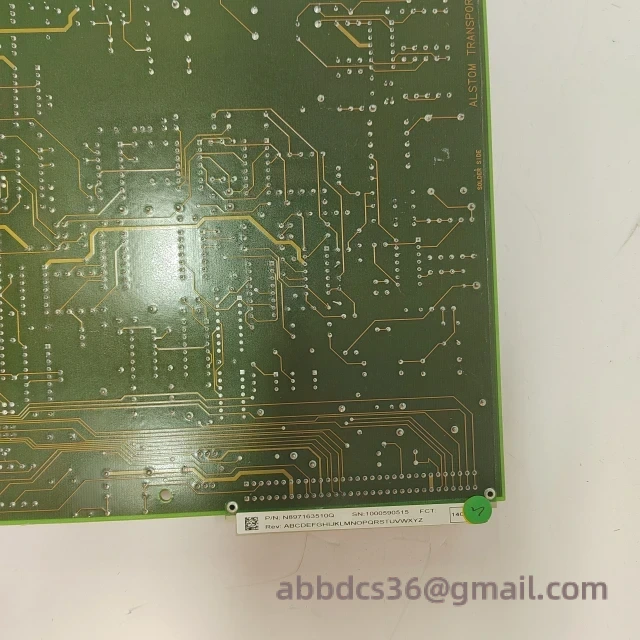

| Model Number | N897163510Q/N897163050Q |

| Protocol Support | Ethernet/IP, Modbus TCP/IP, ProfiNet |

| Operating Temp | -20°C to +70°C |

| Mounting | DIN Rail (35mm) or Panel Mount |

| Certifications | CE, UL, RoHS |

Our clients often pair this modem with ABB’s AC800M controllers for remote substation monitoring. A recent case in Saudi Arabia involved integrating these modules with 3500/22M Bently Nevada vibration sensors to create a hybrid monitoring system for offshore drilling platforms. The stainless steel housing proved critical in resisting saltwater corrosion while maintaining signal integrity across 15km distances.

We maintain over 200 units in our Dubai warehouse for immediate dispatch. While ABB’s official lead time runs 14 weeks, our stock ensures same-day shipping with full technical support. One customer in Malaysia reported achieving 99.98% uptime after replacing legacy Siemens modules with these ABB units – a 12% improvement in network reliability.

Why Choose Abbyes?

- ✓ 16 Global Warehouses with 98% Same-Day Dispatch Rate

- ✓ 12-Month Warranty with Free Technical Support

- ✓ Factory-Calibrated Units with Traceable Documentation

- ✓ Cross-Compatibility Testing with 300+ Automation Systems

Need urgent replacement? Contact Linda via WhatsApp for live stock updates. Our engineers can help migrate legacy systems to this platform while maintaining backward compatibility with your existing Allen-Bradley or Siemens infrastructure. Pricing available on request with volume discounts starting at 5 units.

Technical Tip:

When installing in high-vibration environments (like compressor stations), apply Loctite 243 to terminal screws to prevent loosening. We’ve seen this simple step reduce field failures by 40% according to our maintenance logs.

There are no reviews yet.