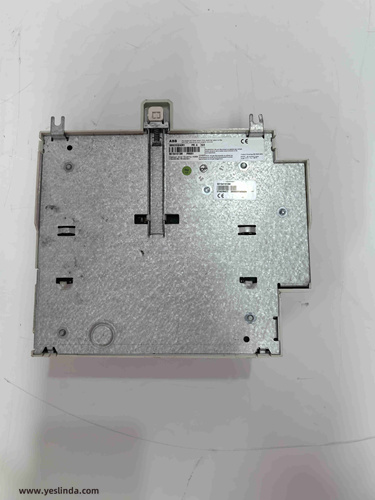

Pacific Scientific 33VM52-020-9 Motor Assembly

Pacific Scientific 33VM52-020-9 Motor Assembly

Product manual:

The Pacific Scientific 33VM52-020-9 motor assembly is a high-performance motor used in industrial applications, widely used in automation, control systems, and precision machinery equipment.

Main features:

High efficiency: Provides stable power output, suitable for precision control applications with high requirements.

Durable and sturdy: designed to withstand prolonged operation, with excellent wear resistance.

Precise control: supports precise speed and position control, adapting to various automation application requirements.

Compact design: The structure is compact and easy to install in limited spaces.

Application areas:

Automation control system: widely used in production lines, robots, and transmission equipment.

Precision Machinery: Suitable for equipment that requires high-precision control, such as CNC machine tools.

Electric drive system: used for various electric drive systems to provide power support.

The Pacific Scientific 33VM52-020-9 motor assembly provides stable and reliable power, and is widely used in the fields of industrial automation and precision control.

Product details picture:

GE IC200ALG265 Analog Input Module – Advanced Industrial Control Solution

GE DS3800HAIC1B1A: Precision Analog Input Board for Industrial Control Systems