CI543 3BSE010699R1 Communication Interface Module

CI543 3BSE010699R1 Communication Interface Module

Product manual:

The CI543 3BSE010699R1 communication interface module is an industrial communication module provided by ABB,

Mainly used for data exchange and communication with other automation equipment or control systems.

This module supports multiple communication protocols and aims to improve interoperability and data transmission efficiency between devices.

Main features:

Multi protocol support:

Supports multiple industrial communication protocols, such as Modbus, Profibus, Ethernet, etc,

Ensure compatibility with automation equipment from different manufacturers.

High data transmission rate:

Provide high-speed data transmission to meet the needs of real-time data exchange, suitable for scenarios that require efficient data communication.

Enhanced interoperability:

Enable seamless connection and communication between different control systems, PLCs, and devices,

Improve the flexibility and scalability of the system.

Compact design:

The compact module design facilitates installation within a limited space,

Adapt to the needs of various industrial control cabinets and automation equipment.

Reliable communication:

Equipped with highly reliable communication capabilities, ensuring stable operation in industrial environments and reducing the risk of communication interruptions.

Flexible configuration:

Provide flexible configuration options, allowing users to configure different communication protocols and connection methods according to their actual needs.

Application areas:

Automated production line: used for data exchange between different equipment and control systems to ensure seamless connection of the production process.

Process control system: In complex process control systems, it serves as a communication bridge between devices to ensure timely transmission of data.

Energy management: Connect with energy monitoring systems, distributed control systems, and other devices to achieve data sharing and monitoring.

Robot control system: used for communication between robots and central control systems to ensure efficient collaborative work.CI543

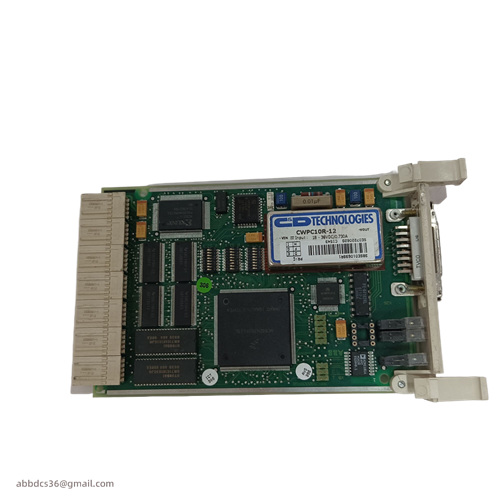

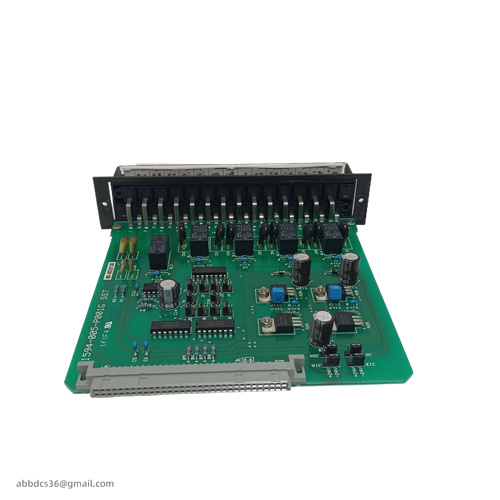

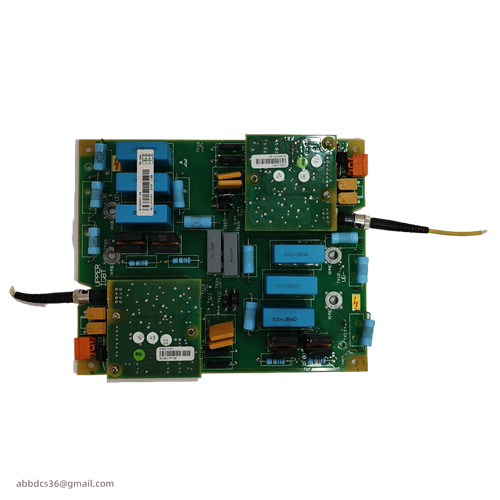

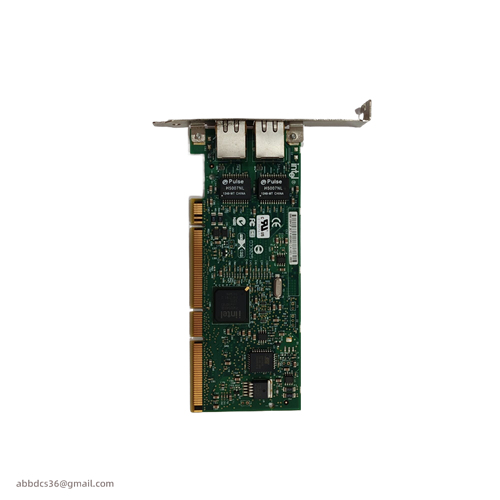

Product details picture:

ABB PM891K02 Controllers – Advanced Industrial Control Solutions