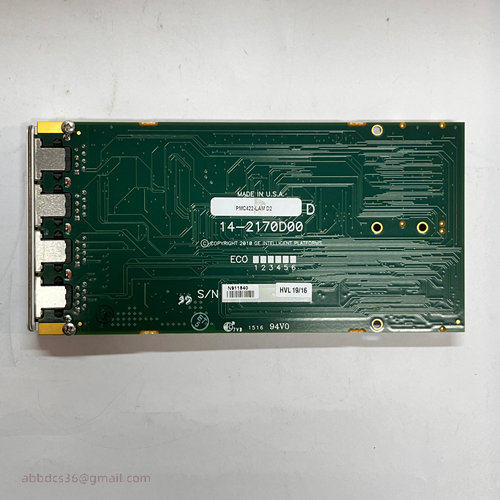

GE PMC422-LAM D2 Controller Module – Analysis of Module Functions and Characteristics

This module belongs to a type of logic and equipment control unit in GE industrial control systems,

Commonly used in process control, equipment coordination, data collection and other scenarios, it is one of the key components responsible for “command and dispatch” in the system.

◆ 1. Reliable core control processing capability

PMC422-LAM D2 is equipped with a stable logic processing unit, which can quickly complete various control logic operations,

Including mode switching, state judgment, and command output execution, making the operation of on-site equipment more coherent and orderly.

◆ 2. Flexible on-site signal processing

The module is capable of receiving various signals from sensors, relays, and equipment terminals,

Filter, judge, and convert the corresponding data, and then hand over the processed data to the system main controller or directly execute the action.

◆ 3. High compatibility and convenient system integration

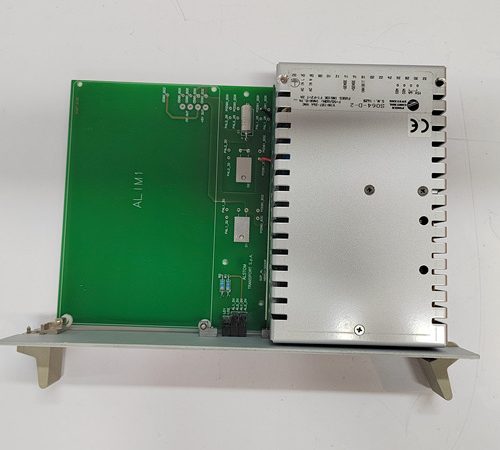

It has good compatibility with GE’s control platform interface, with smooth networking, expansion, and cascading.

Whether used for retrofitting existing systems or as an extension control unit to add new cabinets, it is relatively easy to connect.

◆ 4. Industrial grade stability and anti-interference performance

The module has multiple protections such as electrical isolation, EMI suppression, and input protection,

Capable of withstanding common industrial environmental issues such as noise, voltage fluctuations, and transient interference, ensuring long-term operation without chain failure.

◆ 5. Intuitive operation status

The front panel is usually equipped with status indicators, communication lights, or fault display points,

Facilitate engineering personnel to quickly determine module status and locate issues during operation and maintenance.

◆ 6. Common application locations

Equipment Control and Automation Process Management

Logical Expansion of DCS/PLC Control System

Coordination and control of crew and process stations

Industrial signal acquisition and processing

Interlocking logic management of critical execution links

Leave a comment

Your email address will not be published. Required fields are marked *