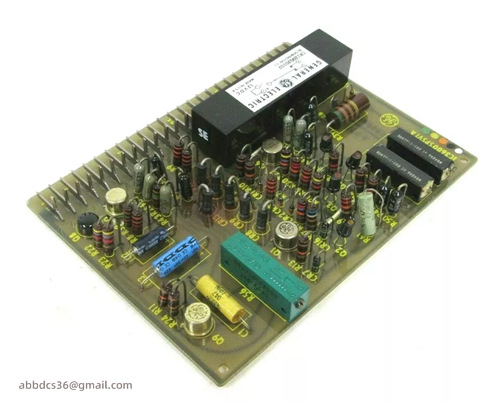

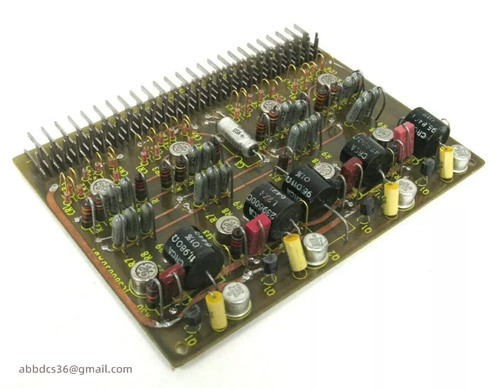

IC3600SOSF gas turbine control module

IC3600SOSF gas turbine control module

Product manual:

GE IC3600SOSF is a gas turbine control module belonging to GE’s Speedtronic series products, designed specifically for gas turbine systems to perform critical monitoring and control tasks. The following is the detailed information of the module:

Core functions

Gas flow control:

Manage gas input to ensure fuel supply matches load demand.

Temperature monitoring and protection:

By monitoring the temperature of the gas turbine in real-time and providing overheat protection function, equipment damage can be avoided.

Speed regulation:

Adjust the speed of the gas turbine to adapt to different operating conditions and power requirements.

Signal processing:

Receive and process signals from temperature sensors, pressure sensors, and speed sensors, and convert them into standard signals required by the control system.

Logical control:

Execute complex logical algorithms to ensure the stable operation of gas turbines.

technical specifications

Input signal:

Supports analog signal input, such as temperature, pressure, and speed signals.

Digital signal input, used for status monitoring and safety protection.

Output signal:

Provide analog or digital control signals for gas valves, ignition devices, or other actuators.

Power requirements:

Working voltage: 24V DC or 48V DC (depending on system configuration).

Environmental conditions:

Working temperature:- 20 ° C to+70 ° C.

Humidity range: 0% -95% (without condensation).

Interface and Connection:

Standardized multi pin interface, suitable for modular installation of GE Speedtronic systems.

application area

Gas turbine control:

Manage key operating parameters of turbines, optimize efficiency, and extend service life.

Energy production and distribution:

Implement intelligent control of gas turbines in power plants to improve power output stability.

Industrial automation:

Used for precise thermal control in complex industrial processes.

Product details picture:

Fanuc A20B-2100-0762/08C – Advanced Control Module for Precision Manufacturing

GE FANUC IC200USB001C – Advanced Communications Option Board