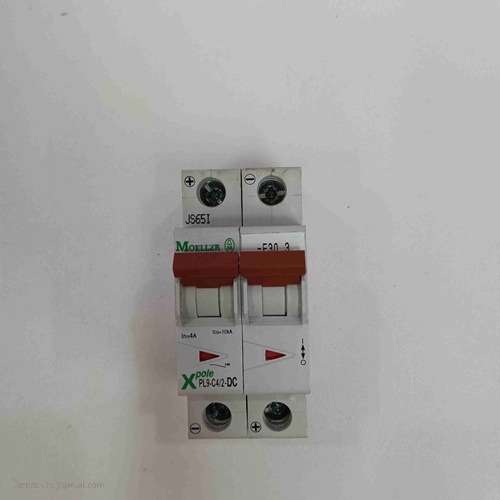

EATON PL9-C4-2-DC Circuit Breaker

EATON PL9-C4-2-DC Circuit Breaker

Product manual:

EATON PL9-C4-2-DC miniature circuit breaker is a modular miniature circuit breaker designed specifically for direct current (DC) applications,

Widely used in DC distribution systems, such as industrial automation, power systems, communication equipment, and new energy systems.

Here are its detailed product information and application areas:

1、 Basic Product Information

Product Model: EATON PL9-C4-2-DC

Type: Miniature Circuit Breaker (MCB)

Current rating: 4A

Number of poles: 2 poles (for bipolar DC applications)

Voltage level: typically supports up to 220V DC (per pole) or 440V DC (when connected in series with 2 poles)

Release curve: C-type (C Curve, suitable for medium inductive loads)

Installation method: DIN rail installation

Standard certification: Complies with IEC/EN 60947-2 or IEC/EN 60898 (DC version)

2、 Product Features

Specially designed for DC systems: Unlike ordinary AC MCBs, it is specifically designed for DC voltage breaking and has strong arc extinguishing capabilities.

Bipolar protection: Disconnect the positive and negative poles or two positive poles respectively, suitable for different DC topologies.

C-type tripping characteristic: suitable for slight inductive loads such as small DC motors, relay circuits, etc.

High breaking capacity: It has good short-circuit protection capability, commonly 6kA.

Compact structure: suitable for high-density installation in limited space.

3、 Typical application areas

Industrial automation system

PLC control cabinet, sensor power supply circuit, DC relay control circuit

DC drive device, solenoid valve, and branch protection for small loads of motors

Solar Energy and Energy Storage System (Photovoltaic DC System)

Used for photovoltaic combiner boxes, DC distribution cabinets, and energy storage battery pack circuits

Provide branch protection and rapid isolation for DC buses or subsystems

Communication base station and data center

Circuit protection of communication equipment DC power supply system (such as -48V DC)

Branch isolation open circuit between UPS backend or battery pack

Transportation and Rail Transit Equipment

Power supply protection for electric traction system, DC lighting, and electrical control equipment

Suitable for DC power supply scenarios such as subways and trams

DC charging system (EV field)

DC side protection for electric vehicle charging stations, particularly suitable for low-power branches or control circuits

Input/output protection of power module

Product details picture:

ABB PM825 3BSC970121R1 CPU Processor Controller Module, Precision Control for Industry 4.0

ABB RC527 Fan Unit – Industrial Cooling Solution, ABB RC527 3BSE008154R1