Honeywell 51405098-100 Interface Module

Product manual:

The Honeywell 51405098-100 interface module is a modular component designed specifically for industrial automation and control systems, used to support communication interfaces for various industrial protocols and devices. It is widely used in Honeywell’s distributed control systems (DCS) and other automation systems, providing a reliable and efficient data transmission bridge between controllers and field devices.

Product Overview

Brand:

Honeywell

model:

51405098-100

Type:

Interface Module

Function:

Provide multiple communication interfaces to adapt to different industrial field devices

Support data transmission, protocol conversion, and signal management

main features

Multi protocol support:

Supports various communication protocols such as Honeywell proprietary protocols, Modbus, Ethernet, TCP/IP, etc.

High compatibility:

Can be connected to different models of DCS, PLC, sensors, and actuators, with strong compatibility.

Modular design:

Easy to integrate and expand, supporting flexible system configuration.

Real time communication capability:

Low latency and high bandwidth data transmission to meet real-time control requirements.

Built in diagnostic function:

Provide operational status monitoring and fault detection to improve maintenance efficiency.

Industrial grade design:

Featuring high anti-interference and reliability, suitable for harsh environments.

technical specifications

Detailed parameter information

Supports protocols Modbus, Ethernet, TCP/IP, and Honeywell proprietary protocols

Power requirement: 24V DC or powered by the system

Power consumption ≤ 5W

Interface type standard industrial communication interface (such as RS485, Ethernet, etc.)

Data rate support up to 1 Gbps data transmission rate

Working temperature range -20 ° C to+60 ° C

Storage temperature range -40 ° C to+85 ° C

Humidity range 5% to 95% (non condensing)

Installation method: DIN rail or cabinet installation

Diagnostic function supports real-time error logging and alarm function

Compact size module, space saving design

Typical applications

Oil and gas:

Manage the communication of on-site equipment such as flow meters and valve controllers.

Power industry:

Used for equipment integration in automation control of power plants and substations.

Chemical manufacturing:

Realize data exchange and control between key production equipment.

Water treatment:

Used for monitoring and controlling the operating status of pumps, valves, and sensors.

Intelligent manufacturing:

Provide stable communication interfaces in complex production lines and support data sharing between devices.

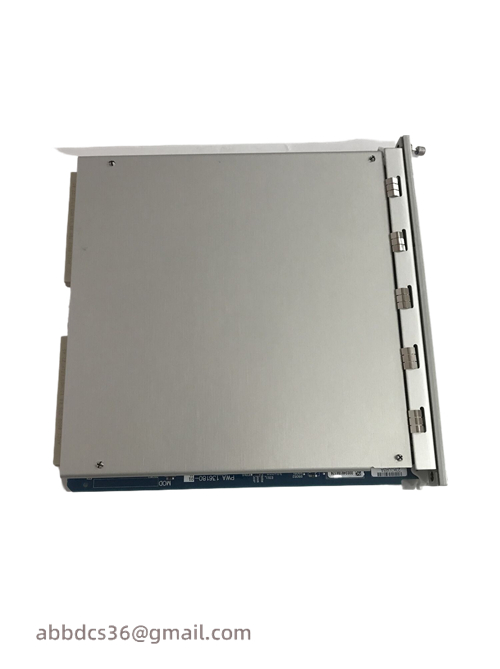

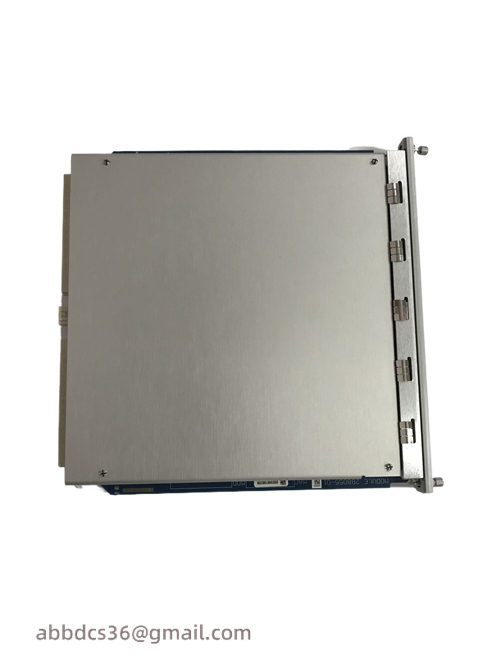

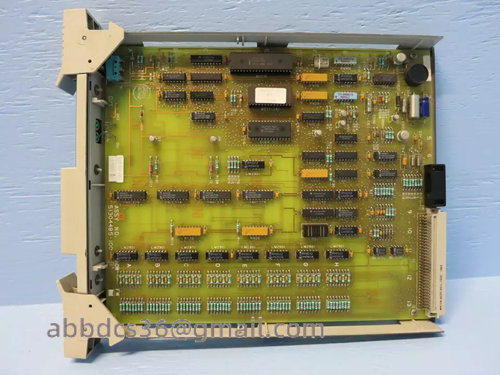

Product details picture:

.jpg)