SHINKAWA MP-2S excitation controller

SHINKAWA MP-2S excitation controller

Product manual:

Main features:

Accurate excitation current control:

By adjusting the excitation current, the speed and output characteristics of the motor can be precisely controlled to improve its performance and operational efficiency.

High stability:

Adopting advanced control algorithms can effectively reduce fluctuations during motor operation, improve system stability and response speed.

Real time monitoring and feedback:

Provide real-time feedback function, monitor the status of motor excitation current, and automatically adjust control parameters as needed to ensure that the motor operates at its optimal working state.

Multiple protection functions:

Equipped with protection functions such as overvoltage, overcurrent, and overtemperature to prevent damage to the motor system due to faults or abnormal situations.

Strong compatibility:

Supports excitation control for multiple types of motors, compatible with multiple motor drive systems, and easy to integrate with existing equipment.

Compact design:

The compact structural design makes it easy to install and integrate into various industrial equipment, occupying less space and reducing installation complexity.

Energy saving and efficiency:

Efficient excitation control technology can optimize the operational efficiency of motors, reduce energy consumption, and improve overall system performance.

Application areas:

Generator set: Used in the generator control system to regulate the excitation current and ensure stable output of the generator.

Electric motor drive system: used for precise control of electric motors, improving the efficiency and performance of the drive system.

Industrial automation: In various automation equipment, optimizing motor performance and improving production efficiency by controlling excitation current.

Energy management system: used to control motors in the power system, reduce energy waste, and improve energy utilization efficiency.

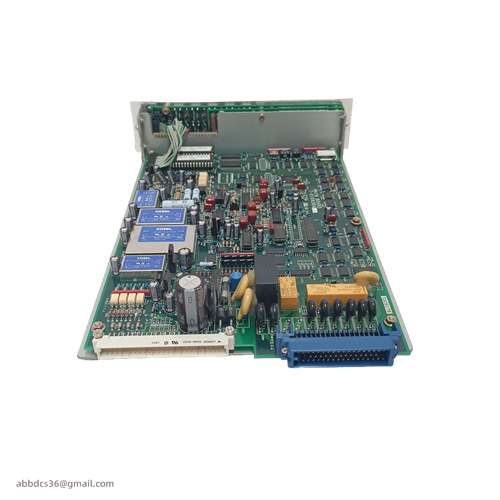

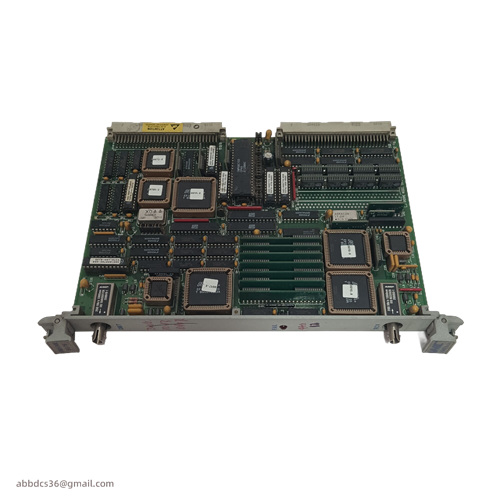

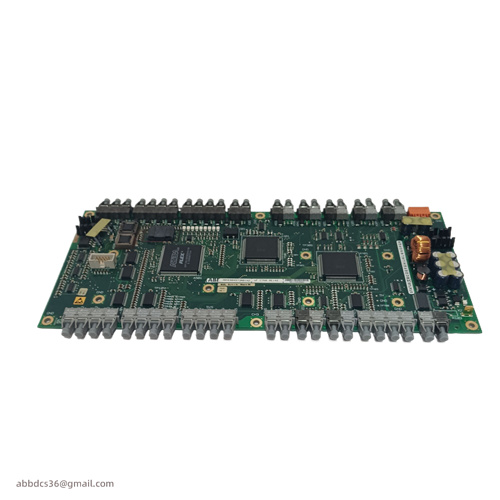

Product details picture:

SHINKAWA VM-5Y1-02: VM-5 Series Monitor, Advanced Industrial Display